Longboard wheels are typically made of polyurethane, a durable and shock-absorbent material. Polyurethane is a type of plastic that is popularly used for longboard wheels due to its strength, flexibility, and resilience.

It is a highly versatile material that can be molded into various shapes and sizes to suit different riding styles, terrains and speed levels. Longboard wheels made of polyurethane are generally more durable and long-lasting than those made of other materials like plastic or rubber. They are also known for their excellent grip and rebound, which help riders maintain better control and stability while riding. Overall, the type and quality of the polyurethane used in longboard wheels will have a significant impact on the ride quality, speed, and overall performance of the board.

Credit: www.mellowboards.com

Polyurethane (Pu)

Longboard wheels are an essential component of the longboarding experience. They are responsible for providing the necessary grip, control, speed, and stability needed for riders to maneuver their longboards effectively. Longboard wheels are made from a variety of different materials, and among them, the most common material is polyurethane (pu).

Description Of Pu As The Most Common Material Used For Longboard Wheels

Polyurethane (pu) is a versatile, synthetic material that offers excellent durability and elasticity. It is a bonded polymer that can be molded into different shapes and forms, making it ideal for manufacturing longboard wheels. Pu is the most popular choice for longboard wheels because it provides better grip, stability, and shock absorption.

Properties Of Pu, Including Hardness And Density

The hardness and density of pu are two essential factors that determine the quality and performance of longboard wheels. The hardness of pu is measured using the durometer scale, which ranges from 1 to 100. The higher the number on the scale, the harder the material is.

Typically, longboard wheels range from 70 to 90 on the durometer scale, with harder wheels being more suitable for cruising and sliding, while softer wheels are better for carving and cruising. The density of pu is another critical factor that affects the performance of longboard wheels.

A higher density pu wheel will have more weight, making it more stable at high speeds, while a lower density wheel will be more lightweight and comfortable for cruising and carving.

Importance Of Pu’S Rebound And Resistance To Wear And Tear In Longboarding

Pu’s rebound and resistance to wear and tear are essential for the longevity and performance of longboard wheels. Rebound refers to the wheel’s ability to bounce back after coming in contact with the ground. A higher rebound wheel will provide better grip, speed, and control.

On the other hand, resistance to wear and tear is vital for ensuring the longboard wheel’s durability, especially when exposed to different weather conditions and surfaces. A higher-quality pu material will provide greater resistance to wear and tear, making it last longer than a low-quality one.

Discussion Of The Various Types Of Pu Used In Longboard Wheels

Pu comes in different types, each with its unique properties, making it suitable for different types of longboarding.

- Standard pu – the most common and cost-effective type of pu material used in longboard wheels

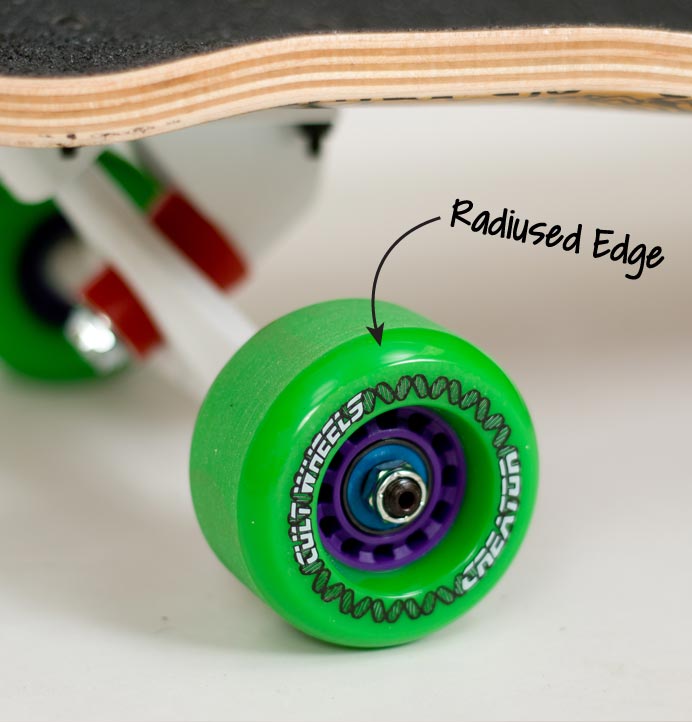

- Rounded lip – a type of pu that features a rounded lip, giving it better grip and traction

- Square lip – a type of pu that has a square lip, providing more stability and control

- Beveled edge – a type of pu with a beveled edge, making it suitable for faster speeds and sliding

By understanding the different types of pu, longboard riders can choose the ideal longboard wheels for their riding style and terrain.

Core Materials

Longboard wheels are an important component of longboarding, and they come in handy when performing different styles of riding on various terrain types. The wheels are made up of different materials, each having its own unique characteristics that impact performance.

One of the most crucial components of longboard wheels is the core material.

Explanation Of The Role Of Core Materials In Longboard Wheels

The core material of a longboard wheel is a crucial component that determines the wheel’s structure and characteristics. The core is responsible for holding the bearing in place, which allows the wheel to spin. Without the core, the wheel would not be able to rotate.

Thus, the core material directly impacts the stability, speed, and overall performance of the wheel.

Types Of Core Materials, Including Plastic And Aluminum

There are two primary types of core materials used in longboard wheels: plastic and aluminum. Plastic cores are typically found in cheaper, lower-end wheels and are softer, which can provide more grip on the roads. Aluminum cores, on the other hand, are used in higher-end wheels that require more precision and durability.

Aluminum cores are stiffer and provide a smoother and faster ride.

Comparison Of The Advantages And Disadvantages Of Different Core Materials

Plastic cores are advantageous in their affordability and provide more excellent traction for riders. They are also lighter, making it easier to perform slides and tricks. However, they lack durability and may not last as long as aluminum cores. Aluminum cores, on the other hand, are highly durable, providing a smoother and faster ride that is more suited for downhill riding.

However, they are more expensive and less forgiving compared to plastic cores.

Discussion Of The Impact Of Core Materials On Wheel Performance

The type of core material used has a significant impact on a wheel’s performance. Wheels with plastic cores tend to provide a greater grip, making them ideal for cruising and carving, while wheels with aluminum cores have more speed and stability, making them suitable for downhill or freeriding.

The core material also affects the weight and durability of the wheel, which can impact a rider’s overall experience. Therefore, choosing the right core material for your preferred riding style is essential to get the most out of your longboard wheels.

Longboard Wheels Made From Scratch Pt 1/3

Additives

Longboard wheels are made of a mixture of materials such as polyurethane, which is the primary element in most wheels, and different additives. Play an important role in enhancing the longboard wheel’s characteristics such as durability and grip.

Description Of The Different Additives Used In Longboard Wheels

Additives are the secondary materials added to the polyurethane mixture to enhance its properties.

- Silica: it is used to increase the wheel’s abrasion resistance and improve its grip. Silica is a common additive in wheels used for sliding and carving.

- Carbon fiber: it is added to the mixture to increase the wheel’s stiffness and strength. Wheels with carbon fiber are perfect for downhill and high-speed riding.

- Graphene: it is a relatively new additive that enhances the wheel’s strength, durability and improves the skater’s grip.

Explanation Of How Additives Enhance Wheel Properties, Such As Grip And Durability

Additives improve the characteristics of longboard wheels in several ways.

- Increasing grip: additives like silica increase the wheel’s friction with the ground, providing better grip and control to the rider.

- Improving durability: additives like carbon fiber improve the wheel’s stiffness and prevent deformation, enhancing its lifespan.

- Enhancing speed: additives like graphene provide a better bond between the wheel and the ground, allowing the rider to achieve higher speeds comfortably.

Examples Of Common Additives, Including Silica And Carbon Fiber

- Silica: as mentioned above, silica is added to polyurethane mixtures to provide better grip. Wheels with a higher percentage of silica are more grippy and suitable for carving and sliding.

- Carbon fiber: carbon fiber is added to polyurethane mixtures to make them stiffer and more robust. Wheels with carbon fiber are perfect for downhill and high-speed riding. It provides a lot of stability, and the rider can confidently tackle turns at high speeds.

Additives play a vital role in enhancing the characteristics of longboard wheels. They improve properties such as grip, durability, and speed, making them suitable for different riding styles. Longboarders need to understand the additives in their wheels to ensure they select the right wheels that suit their riding styles.

Wheel Shapes And Sizes

What Are Longboard Wheels Made Of?

Longboard wheels are a vital component of a longboard and are responsible for ensuring a smooth and safe ride while also impacting performance. Understanding what longboard wheels are made of and how they function is crucial to make an informed buying decision.

One factor to consider is the wheel shape and size, which have a significant impact on the overall performance of a longboard.

Overview Of The Various Shapes And Sizes Of Longboard Wheels

Longboard wheels come in different shapes and sizes, and each has its unique features that cater to specific riding styles and terrains.

- Round shape: this is the most basic wheel shape and is perfect for cruising, carving, and commuting on flat surfaces.

- Square lipped shape: this shape provides more grip and stability at high speeds, making it ideal for downhill riding.

- Bevelled shape: this shape is a hybrid between round and square lipped wheels, offering a balanced performance between speed and grip.

- Small size (60-66mm): these wheels are lighter and provide better acceleration and maneuverability for tricks and technical riding.

- Mid-size (67-72mm): these wheels are well-rounded and provide a balance between speed and maneuverability, making them perfect for cruisers and freeriders.

- Large size (73mm and above): these wheels are heavier and provide better speed and stability, making them ideal for downhill riding.

Explanation Of How Wheel Shape And Size Impact Longboarding Performance

The shape and size of wheels have a great impact on the performance of a longboard, including the speed, grip, stability and maneuverability.

- Round wheels provide better grip but less speed than square lipped wheels.

- Square lipped wheels provide more speed but less grip than round wheels.

- Soft wheels provide better grip for cruising on rough terrains but have slower speed and less slide control.

- Hard wheels provide faster speed and better slide control but less grip, making it suitable for downhill riding.

- Small wheels offer better acceleration and maneuverability, making them perfect for technical riding and tricks.

- Large wheels have better speed and stability, making them ideal for downhill riding.

Discussion Of The Pros And Cons Of Different Wheel Shapes And Sizes

Different wheel shapes and sizes have their pros and cons that cater to specific riding styles and terrains.

- Round wheels are suitable for cruising, carving and commuting, but not ideal for high-speed riding.

- Square lipped wheels are perfect for downhill riding, but not as good for cruising and technical riding.

- Soft wheels are better for cruising on rough terrains, but not ideal for high-speed riding.

- Hard wheels are ideal for high-speed and downhill riding, but not as good for cruising and commuting.

- Small wheels offer better maneuverability and acceleration for tricks and technical riding, but less speed and stability for high-speed riding.

- Large wheels provide better speed and stability for downhill riding, but less maneuverability for tricks and technical riding.

Relationship Between Wheel Shape And Size With Pu And Core Materials

The wheel shape and size are also closely related to the wheel’s pu and core materials. Pu materials can vary in softness, with softer materials providing better grip and smoother ride, while harder materials providing faster speed and slide control.

The core material also plays a role in the wheel’s overall performance, with lighter cores providing better acceleration and maneuverability, while heavier cores providing better speed and stability. It’s important to consider these factors when choosing a longboard wheel to ensure optimal performance.

Understanding the various shapes and sizes of longboard wheels and how they impact performance is critical for any longboard rider. Consider your riding style and terrain to determine which wheel shape and size is best for you, keeping in mind the relationship between the wheel shape and size with pu and core materials to ensure a smooth ride and optimal performance.

Conclusion

Longboard wheels are made of a variety of materials, each of which provide unique benefits and drawbacks. Harder wheels made of polyurethane are ideal for smooth surfaces and faster speeds, while softer wheels made of urethane are better for rough terrain and cruising.

There are also hybrid wheels that combine different materials to provide a happy medium of durability and grip. While there is no one-size-fits-all solution, finding the right longboard wheels can greatly improve a rider’s experience. It is important to consider different factors such as size, shape, durometer, and contact patch when choosing the best wheels for your particular needs.

With proper maintenance and care, longboard wheels can provide a smooth and enjoyable ride for many adventures to come.